DeltaV-Seal™ the tightest, safest and most durable flange gasket in the world.

Designed to replace Spiral Wound and Kammprofile gaskets its fully metal design is robust and easy to handle, enabling a simple, gas-tight installation that is guaranteed to be maintenance-free for the long term. Once installed the connection is non-ductile, static, and never requires re-tightening of bolts or fasteners to maintain tightness. Galvanic corrosion is also mitigated by manufacturing the DeltaV-Seal from a compatible material as the connecting flanges.

Simply leak proof

The DeltaV-Seal is a one-piece, CNC manufactured gasket made from a compatible metal as the flanges it mates with. It boasts three unique, sharp sealing rings that deform on installation, filling any surface irregularities on pipe flanges to form the perfect seal.

The seating force required for the material to flow effectively is lower than for any spiral wound gasket. Once placed between the connecting flanges, a permanent static and leak-proof seal is created. Total integrity, complete peace of mind.

Zero deterioration

Gasketed flanged connections found in corrosive sensitive environments such as seawater and hydrocarbon services is subject to corrosion and degradation. The deterioration is caused when you have two dissimilar metals in an assembly that are electrically connected in an electrolyte.

With the DeltaV-Seal, galvanic corrosion in the connection is mitigated, as it is manufactured in a compatible material as the mating flanges and the connections are electrically conductive.

Seamless interaction

Fluctuating temperatures force metal flanges and seals to expand and contract. As current ductile seals are not made from the same materials as flanges, these rates of expansion and contraction differ, with the seals eventually dissolving or changing properties over time. DeltaV-Seal is different.

Made from a compatible metal as the flange - and certified resistant to vibration, pressure pulses and temperature changes – the seal matches its movement, contracting and expanding in seamless unity and forming an enduring, non-ductile, metal-to-metal partnership. The perfect match.

Install and forget

DeltaV-Seal marks a new beginning for industrial piping. Not only no leaks, but no re-tightening, no disintegration, no blowout or fire risk, and no safety concerns – in other words, no worries.

Revolutionary seal, transformative benefits.

The DeltaV-Seal™ is designed to replace Spiral Wound and Kammprofile gaskets, solving the leak challenge once and for all. The result is instant, compelling and measurable business benefits - for all businesses - with enhanced safety, sustainability and economic performance.

Products

Each Pipeotech product has been designed and engineered to provide a better than gas tight sealing for industrial applications. Our products are precision CNC machined from a single metallic plate, maintaining full product traceability, and enabling sealing where chemical resistance, temperatures or galvanic corrosion would be an additional for legacy seals.

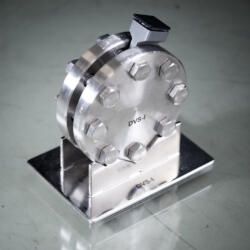

DeltaV-Seal flange gasket

The DeltaV-Seal is the tightest, safest and most durable flange gasket technology in the world. Designed to replace Spiral Wound and Kammprofile gaskets its fully metal design is robust and easy to handle, enabling a simple, gas-tight installation that is guaranteed to be maintenance-free for the long-term.

Once installed the connection is non-ductile, static, and never requires re-tightening of bolts or fasteners to maintain tightness. Galvanic corrosion is also mitigated by manufacturing the DeltaV-Seal from a compatible material as the connecting flanges.

DeltaV-Seal

Metal-to-Metal sealing, the logical replacement for FFKM “O” Ring Seals.

The Pipeotech DVS-H is an ‘O’ ring style seal that features the patented DeltaV sealing ridge to provide better than gas tight sealing for industrial ‘O’ ring sealing applications. The 100% metal construction allows material choice to be utilized compatible to the service of the system, and in addition allows in-service performance at temperatures well in excess of FFKM seals currently provide.

DeltaV-Seal I

Detect pressure, temperature, flow, vibration and more

Pipeotech’s DeltaV-Seal I provides all the benefits of our traditional DeltaV-Seal with the added capability to add a sensor which can detect pressure, temperature, flow, multiflow, vibration, etc. A smart gasket assists operators in many ways, improving systems and increasing reliability and cost effectiveness of systems.

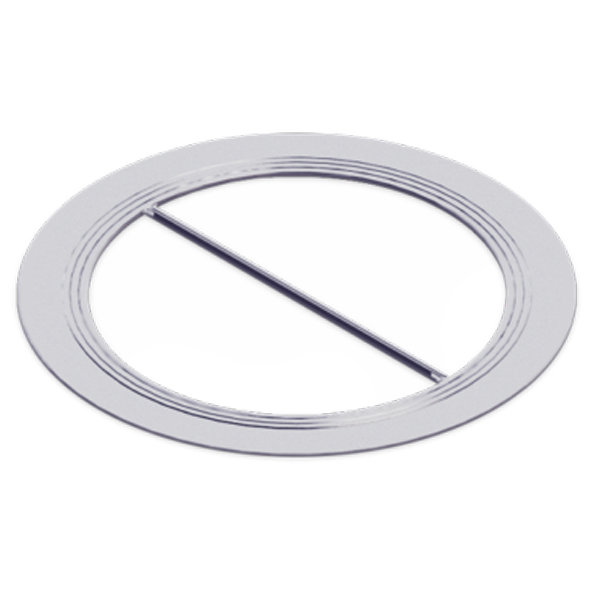

DeltaV-Seal custom designs

To find out more on our ovals, separators, other couplings, contact us

The patented DeltaV-Seal™ technology can be made to meet customers’ specific requirements in both oval versions or split gaskets.

Trusted by

"In pipeline systems for LNG, liquefied natural gas, we now exclusively use DeltaV-Seal. The enhanced reliability of the entire system means less maintenance and unplanned service calls, giving us huge savings"

Jacob Stebekk

SALES MANAGER, INTERGAS AS