Pipeotech launch new 304L stainless steel DeltaV-Seal for nitric acid service

James Knights on News · Jun 21, 2023

Working with the chemical industries it is clear Nitric Acid is a particularly challenging chemical to keep within bolted flange joints. Current industry practice on bolted flange joints containing Nitric Acid is to utilize a special blend of PTFE and other chemicals as a gasket. Discussions between Pipeotech and the industry have highlighted the current industry practice is to regularly replace their current gasket, typically every 6 to 12 months. Every time a legacy semi-metallic gasket is changed the nitric acid system must be emptied and made safe, a significant cost in both time and resources.

– Every time a legacy semi-metallic gasket is changed the nitric acid system must be emptied and made safe, a significant cost in both time and resources.

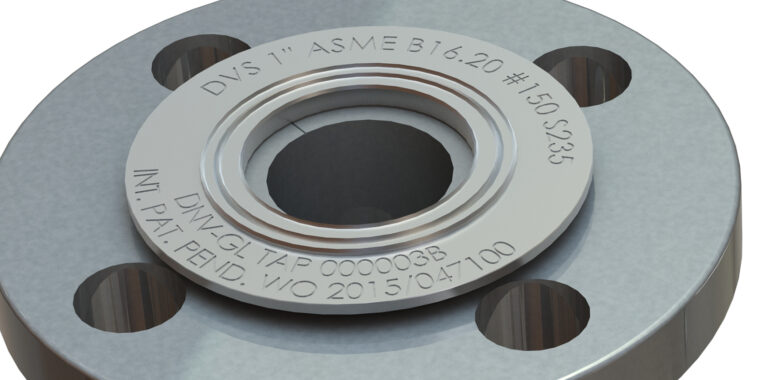

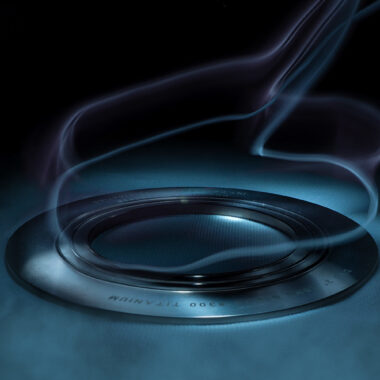

Pipeotech have developed a DeltaV-Seal specifically designed and engineered for Nitric Acid service, normally within fertilizer plants. The new DeltaV-Seal is precision machined from 304L stainless steel to a similar design to Pipeotech’s current gaskets. Due to the versatility of the DeltaV-Seal it allows the one-piece precision CNC machined product to be manufactured in materials compatible to the facilities incumbent pipework system.

As with all Pipeotech’s metallic gaskets, the 304L DeltaV-Seal is designed and engineered specifically to replace legacy spiral wound and Kammprofile gaskets. The fully metallic construction of the DeltaV-Seal is robust and easy to handle, enabling a simple, gas-tight installation that is certain to be maintenance-free for the long term. Once installed the connection is non-ductile, static, and never requires re-tightening of bolts or fasteners to maintain tightness. All DeltaV-Seal materials have been proven extremely durable particularly to vibration and pressure pulse cycles.

Pipeotech’s new 304L flange gasket has undergone a significant amount of testing, beyond the standard industry requirements within EN13555. The new DeltaV-Seal 304L has been tested up to 40 BarG pressure at temperatures of 20 °C, 200 °C, and 400 °C, to establish its elasticity, relaxation, and leakage rates based on gasket stress. Traditional gaskets only complete these tests at ambient temperatures.

Download the 304L DeltaV-Seal product sheet

– Pipeotech’s 304L DeltaV-Seal will save fertilizer plants millions of dollars by significantly increasing the time between gasket changes. Increasing the time between gasket changes significantly reduces maintenance costs and increases the available uptime of nitric acid units.

Andrew Patrick, CEO, Pipeotech

The new 304L DeltaV-Seal developed in partnership with industry is the perfect gasket for the bolted flange joints of nitric acid piping. Replacing existing gasket technology, the new 304L stainless steel DeltaV-Seal is significantly more resistant to nitric acid than the technology it replaces. Pipeotech’s 304L DeltaV-Seal will save fertilizer plants millions of dollars by significantly increasing the time between gasket changes. Increasing the time between gasket changes significantly reduces maintenance costs and increases the available uptime of nitric acid units.

Ready to discuss your sealing challenge?

Contact UsMore from News

DNV Type Approval Certificate Renewed

James Knights on News · Oct 22, 2024

We're pleased to announce the renewal of our DNV GL Type Approval, valid until 2029. The DNV GL Type Approval (Certificate TAP000003B) celebrates the testing and dedication to achieving the tightest…

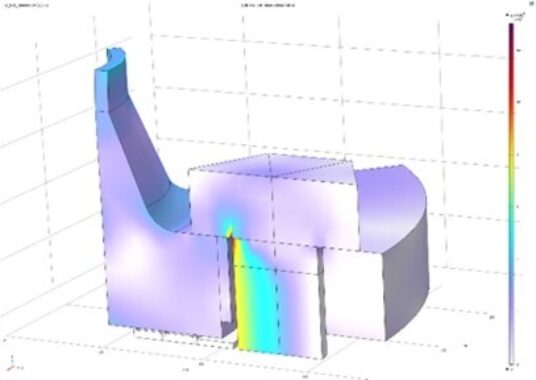

COMSOL Multiphysics FEA Modelling of Gasketed Bolted Flange Joints

James Knights on News · Jul 08, 2024

Imagine a future where in extreme environments it is possible to model and simulate a gaskets performance and know the lifetime of a bolted flange joint, sealed with a DeltaV-Seal. Pipeotech's…

Frequently Asked Questions

James Knights on News · Mar 17, 2023

The DeltaV-Seal is revolutionising static sealing, one gasket at a time. The gasket provides the tightness and durability of a metal-to-metal seal with the ease of application of a spiral wound,…

Proposed European PFAS ban officially submitted – it’s potential impact on PTFE gaskets.

James Knights on News · Mar 17, 2023

On the 13 January 2023, The Netherlands, Germany, Denmark, Sweden and Norway took the first formal step towards a European ban on polyfluoroalkyl substances (PFAS) by jointly submitting a restriction…

We're growing - and moving to a bigger office space!

James Knights on News · Mar 06, 2023

We are excited to announce that Pipeotech’s Oslo team is moving to a new location within Oslo. The big reason? We are growing in both the number of clients and number of applications where a…

DeltaV-Seal Gaskets for peroxide service featured in Fluid Handling Pro

James Knights on News · Dec 21, 2022

Pipeotech's project with a global manufacturer of peroxide has been featured within Fluid Handling Pro. The article details the design considerations for a gasket utilized in an extremely pure…

Pipeotech Q3 Newsletter

James Knights on News · Oct 20, 2022

Another quarter is in the books here at Pipeotech. Q3 brought many opportunities for the company. Engineers and executives met with clients across the globe and attended various events to share the…

Pipeotech, featured in Fluid Handing Pro

Jo Shailes on News · Nov 15, 2021

Vibration Analysis Part of the DNV GL Type Approval for the Pipeotech DeltaV-Seal The weakest link in industrial piping systems is the gasket. Conventional semi-metallic gasket technologies are not…

Pipeotech, featured in Sealing Technology & World Pumps

Jo Shailes on News · Oct 27, 2021

Following extensive leakage testing, carried out under cryogenic conditions in a laboratory programme, Pipeotech has extended coverage all the way down to applications running at a temperature of…

Valve World features DeltaV-Seal™

Geir Otto Amundsen on News · Sep 15, 2021

In July 2021, one of the sealing industry's most widely circulated publications, Valve World, featured Pipeotech CTO Jan Oredsson inspecting a DeltaV-Seal gasket on its front cover, hailing Pipeotech…

Andrew Patrick takes over as Pipeotech interim CEO

Geir Otto Amundsen on News · Jun 23, 2021

Pipeotech has appointed Andrew Patrick as the company’s interim chief executive following the resignation of outgoing CEO Henrik Sollie. Patrick steps into the interim role from his current position…

Cryogenic milestone for DeltaV-Seal™

Geir Otto Amundsen on News · Mar 31, 2021

Pipeotech gasket, DeltaV-Seal™ is engineered for long term use, all the way down to applications running at -196°C, based on stellar results of cryogenic leakage tests at a pre-eminent European…

DeltaV-Seal™ - The end to fugitive emissions?

Geir Otto Amundsen on News · Mar 16, 2021

At Pipeotech we believe that the concept of 'acceptable leakage' is unacceptable and that flange-born fugitive emissions are an avoidable threat. As part of our mission to spread this message it was…

Corrosion and integrity specialist Jan Oredsson joins Pipeotech

Geir Otto Amundsen on News · Dec 02, 2020

Pipeotech has sealed the deal on an exciting new addition to its team by bringing in internationally recognized pipeline integrity and corrosion expert Jan Oredsson.Oredsson has extensive experience…

Pipeotech recruits Andrew J. Patrick as new Head of Business Development

Geir Otto Amundsen on News · Oct 05, 2020

Pipeotech is looking to “supercharge” its global growth with the recruitment of Andrew Patrick to the new role of Head of Business Development. Patrick, previously EVP Global Sales at Clock Spring…

Pipeotech joins the European Sealing Association

Geir Otto Amundsen on News · Jun 28, 2020

Pipeotech is pleased to announce that it has become a member of the European Sealing Association.Established in 1992 as a non-profit making trade association, The European Sealing Association…

To boldly go... Pipeotech joins the Innovation Norway, Explorer

Geir Otto Amundsen on News · Apr 22, 2020

We’re pleased to announce that at the beginning of 2020, Pipeotech joined the ranks of one of Norwegian Industry’s most exclusive clubs, The Explorer. Opened by Norwegian Prime Minister Erna Solberg…

From subsea to life on land - gasket technology follows Darwinism

Geir Otto Amundsen on News · Aug 28, 2019

As featured by Yahoo Finance news via Cision PRNewswireMetal-to-metal sealing technology is a technique that had previously been reserved for subsea oil and gas applications where meeting the most…

The seal of integrity (a feature article written by Industry Networker Magazine)

Geir Otto Amundsen on News · Jul 01, 2019

In a recent article published by Industry Networker Magazine, Pipeotech and theDeltaV-Seal™ are recognized for significant technological enhancements towards safety, efficiency, cost reduction, and…