Home → Industries → Oil & Gas

Oil & Gas

Safety and emissions compliance are essential to the Oil & Gas industry. An industrial facility or refinery can face the possibility of having thousands of micro-leaks, and until recently the best practice has been to tolerate these leaks on an 'acceptable level'. To some facilities the proper seal or gasket may seem like an afterthought in the grand scheme of oil and gas production. However, anyone who has ever experienced the costly downtime associated with seal or gasket failure knows these products are as crucial to the process as their larger-scale counterparts.

Applications

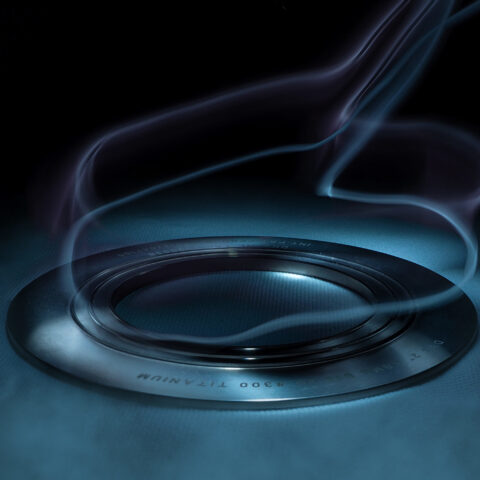

The DeltaV-Seal is the sealing solution that satisfies the requirements of the Oil and Gas industry, as it is effectively gas-tight, firesafe, blowout-safe, and tolerates extreme temperature fluctuation through upstream, midstream, and downstream operations. Utilizing a smarter seal not only means superior sealing performance, it also means a client can operate without ever having to clean a flange or having to maintain it, for the entire operational lifespan of the flange connection.

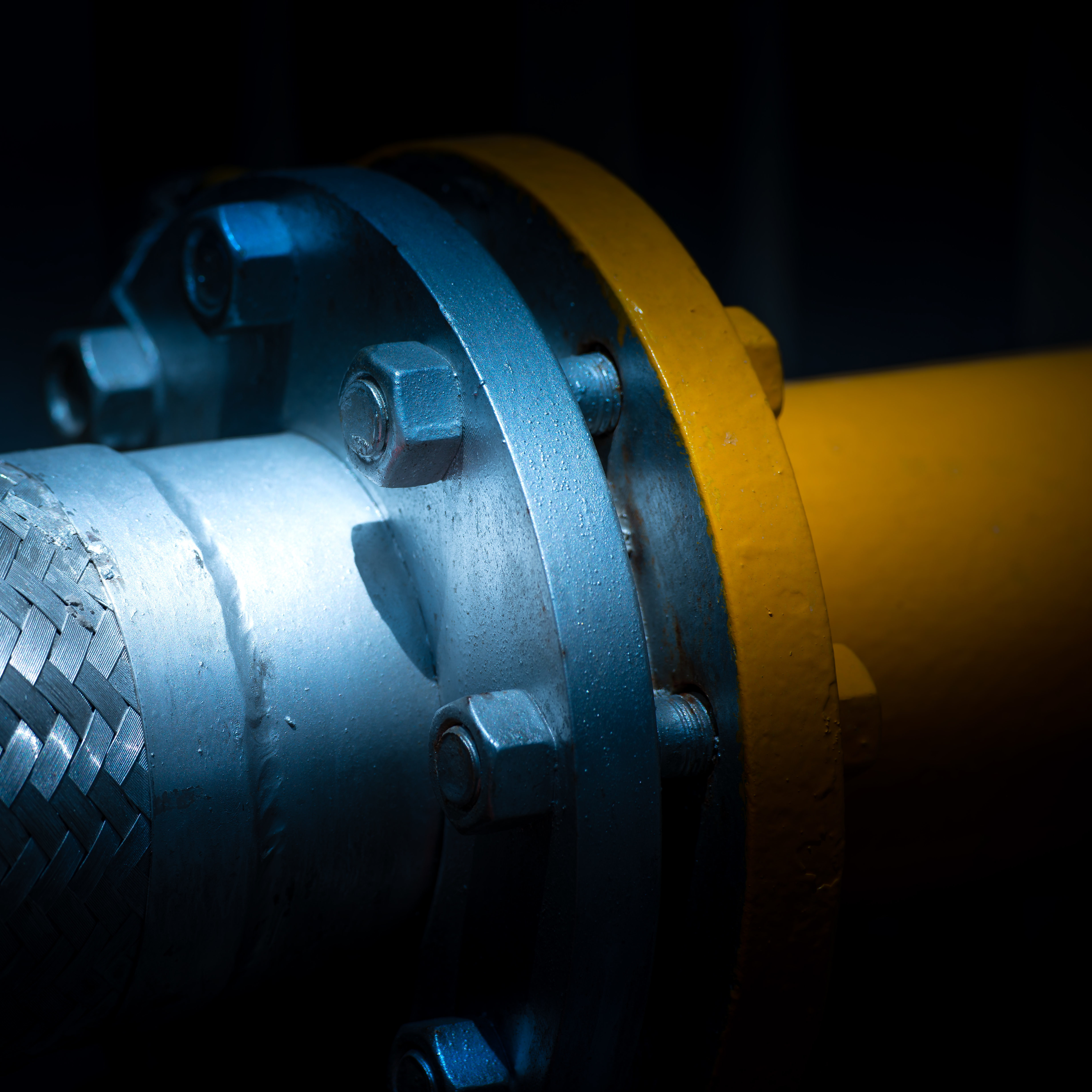

Piping, flanged connections

The integrity of a pipeline is essential in the transportation and processing of oil and gas, as pressures and temperatures associated with production bring inherent danger to a facility and employees. Micro-leaks or 'fugitive emissions' no longer skate under the radar of the EPA or other national environmental protection agencies.

Pressure vessels

A pressure vessel is a closed container designed to hold gases or liquids at a pressure substantially different from the ambient pressure. In the Oil & Gas industry, a pressure vessel is used as a recipient in which physical and chemical processes take place, (often at elevated temperatures and pressures). Leaks connected to a pressure vessel can be fatal and having the right gasket is a low insurance policy.

Heat exchangers

In crude oil refineries Heat Exchangers are used to transfer heat between two or more fluids. The fluids may be separated by a solid wall (tube) to prevent mixing. Depending on the exchanger type, may be separated or in direct contact. Sealing large air-cooled heat exchangers can be challenging, as these heat exchangers are often prone to a lot of corrosion problems, vibration, exchanger leakage, and thermal leakage problems. These challenges are eliminated through a superior sealing strength.