The impact of using DeltaV-Seal™ on flange surfaces

Jo Shailes on Technical Articles · Feb 11, 2022

Pipeotech has conducted flange surface profile measurements in cooperation with Sintef/DNV to investigate the impact of DeltaV-Seal on flange surfaces in bolted flange joints (BFJ).

Flange surface profile measurements

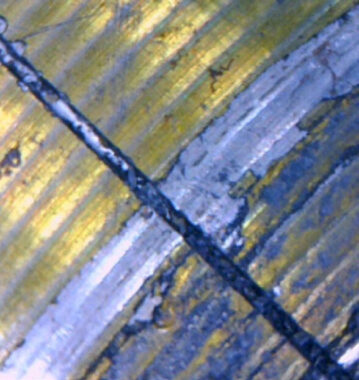

To investigate the impact of 316L DeltaV-Seal on flange surfaces, surface profile measurements were performed after installation of the gasket in 1’’, 6’’ and 12’’ RF flanges, all in #300 and made from 316L. An Alicona Imaging 3D optical-based metrology and imaging system was used for the surface profile measurements and documentation.

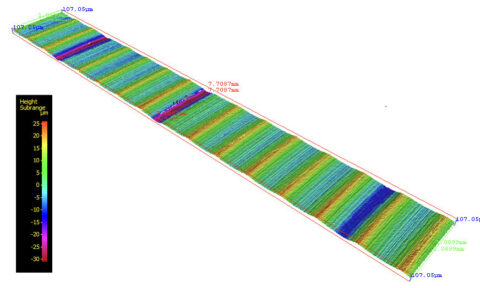

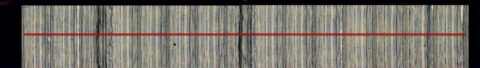

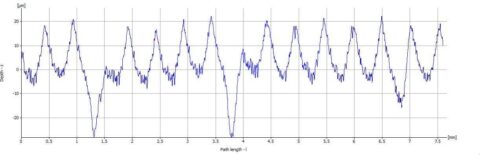

Typical result and documentation presentation from the Alicona Imaging system applied to the tested samples is shown below:

Colour-coded 3D surface profile variation visualization showing concentric flange grooves and three locations of DeltaV-Seal interaction with the flange surface. Purple colour: max. depth 30 μm; Red colour: max. height 25 μm.

Optical image of a 1” flange RF surface with the measurement line in red across with a radial distance of 6 mm between the visible outer and inner ridge interaction locations.

Typical flange surface profile of the tested flanges with the three DeltaV-Seal interaction locations clearly visible in-between the machined grooves with a radial distance of 6 mm between the inner and outer ridge gasket/flange surface interaction locations on the X-axis. Max. height on Y-axis is 20 μm and max. depth on Y-axis is 30 μm. RF width: ≈7.5 mm.

To continue reading, download the article here

More from Technical Articles

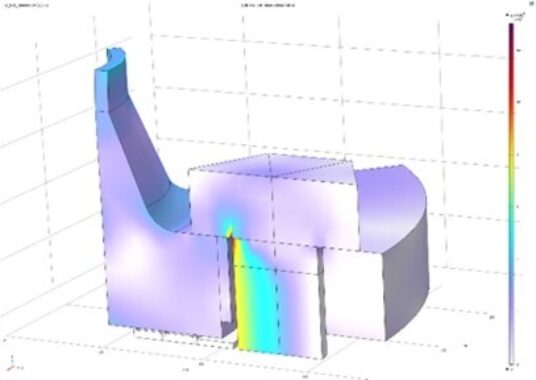

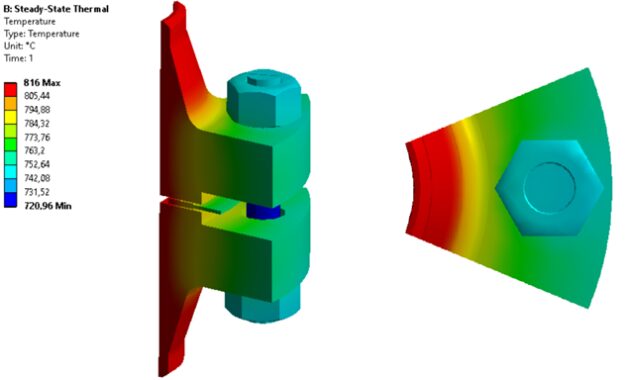

COMSOL Multiphysics FEA Modelling of Gasketed Bolted Flange Joints

James Knights on Technical Articles · Jul 08, 2024

Imagine a future where in extreme environments it is possible to model and simulate a gaskets performance and know the lifetime of a bolted flange joint, sealed with a DeltaV-Seal. Pipeotech's…

DeltaV-Seal 800HT - Assessment of high temperature pipework design for pilot plants

James Knights on Technical Articles · Dec 05, 2022

Ensuring the DeltaV-Seal™ gasket provides gas tight performance even when operating at temperatures as high as 880 °C (1616 °F).

Stability and tightness of damaged flange joints with DeltaV-Seal Gaskets

Jo Shailes on Technical Articles · May 11, 2022

Imperfections on flange faces happen. With more and more companies adopting low emissions business practices, can damaged flange surfaces provide a suitable seal to meet environmental compliance?…

Amended Technical Instructions on Air Quality Control (TA Luft) – What does it mean for Pipeotech and our customers?

Jo Shailes on Technical Articles · Feb 14, 2022

The Technical Instructions on Air Quality Control (TA-Luft), which have been revised in 2021, are a comprehensive instrument for German authorities to control air pollution.

The importance of sealing materials in safe and efficient integrated fertilizer production

Jo Shailes on Technical Articles · Feb 11, 2022

The need to optimize fertilizer plant operations, driven by a range of external and internal influences, means that plant operators must be confident that all equipment is both reliable and high…